CNC Lathe and Milling Machines Market Summary

CNC Lathe: A CNC lathe is a machine tool used for shaping materials such as metal, wood, or plastic by rotating the workpiece while a cutting tool is applied to it to remove material and create the desired shape. CNC lathes are controlled by computer programs that dictate the precise movements of the cutting tool along multiple axes (typically X, Y, and Z). This allows for the production of complex shapes with high precision and repeatability. CNC lathes are commonly used for turning operations, such as cylindrical or conical shaping, threading, facing, and grooving.

CNC Milling Machine: A CNC milling machine is a versatile machining tool used for cutting and shaping solid materials, typically metal, wood, or plastic. Unlike a lathe, which rotates the workpiece, a milling machine holds the workpiece stationary while a rotating cutting tool removes material from it along multiple axes (usually X, Y, and Z). CNC milling machines are capable of performing a wide range of operations, including drilling, cutting, contouring, and slotting, with high precision and efficiency. They are commonly used in the production of complex components, molds, prototypes, and precision parts across various industries.

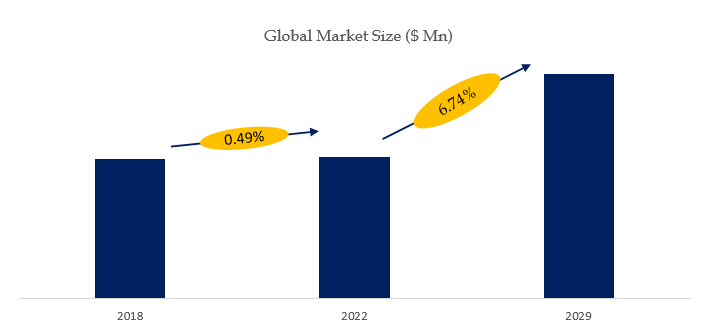

According to the new market research report "Global CNC Lathe and Milling Machines Market Report 2023-2029", published by QYResearch, the global CNC Lathe and Milling Machines market size is projected to grow from USD 21,731.60 million in 2023 to USD 32,142.47 million by 2029, at a CAGR of 5.85% during the forecast period.

Figure. Global CNC Lathe and Milling Machines Market Size (US$ Million), 2018-2029

Based on or includes research from QYResearch: Global CNC Lathe and Milling Machines Market Report 2023-2029.

Market Drivers:

1. Growing Industrialization and Manufacturing Activities: Rapid industrialization, particularly in emerging economies, spurs the expansion of manufacturing activities across diverse sectors. CNC lathe and milling machines play a critical role in meeting the increasing demand for machined components and parts in industries such as automotive, aerospace, consumer electronics, and machinery. The rising adoption of CNC machining technologies in developing markets contributes to market growth and expansion opportunities for machine tool manufacturers.

2. Demand for High-Precision Components: Industries such as aerospace, automotive, medical devices, and electronics require high-precision components with tight tolerances and complex geometries. CNC lathe and milling machines enable the production of such components with exceptional accuracy and surface finish, meeting the stringent requirements of these industries. The growing demand for miniaturization, lightweight materials, and advanced technologies fuels the need for CNC machining solutions capable of delivering precision and quality.

Restraint:

1. Global Supply Chain Disruptions: The CNC machining industry relies on a complex global supply chain for raw materials, components, and machine tool accessories. Disruptions such as material shortages, trade tariffs, transportation delays, or geopolitical tensions can impact the availability and cost of CNC machine components, leading to supply chain bottlenecks and production delays.

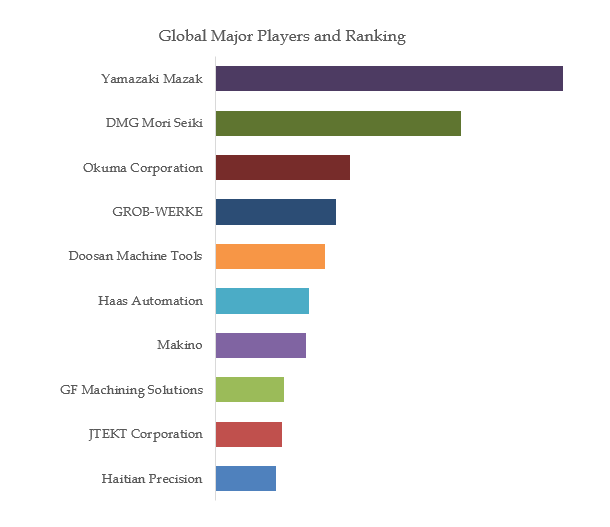

Figure. Global CNC Lathe and Milling Machines Top 10 Players Ranking and Market Share(Continually updated)

Based on or includes research from QYResearch: Global CNC Lathe and Milling Machines Market Report 2023-2029.

This report profiles key players of CNC Lathe and Milling Machines such as Yamazaki Mazak, DMG Mori Seiki, Haas Automation, Doosan Machine Tools, Okuma Corporation.

In 2022, the global top five CNC Lathe and Milling Machines players account for 45.69 % of market share in terms of revenue. Above figure shows the key players ranked by revenue in CNC Lathe and Milling Machines.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.